16.10.2025

While traditional maintenance involves checking systems at fixed intervals, predictive maintenance is one step ahead. Data from the machine itself, such as temperature, vibration or power consumption, is continuously recorded and analyzed. With the help of algorithms and AI models, conclusions can be drawn as to when a component is likely to fail. This means that maintenance can be carried out exactly when it is really necessary, i.e. not too early and not too late.

According to the Industry of Things, predictive maintenance describes a data-based maintenance approach in which sensor values are analyzed and failure probabilities are calculated on this basis in order to avoid unplanned downtimes.

The basic principle is simple: machines are equipped with sensors that continuously supply data. This data is collected, processed and analyzed either directly in the machine or via an edge system.

The procedure is usually as follows:

For these processes to function smoothly, reliable hardware is needed at the edge. After all, not all data can or should always be sent to the cloud - low latency times, data protection and real-time requirements often make local processing necessary.

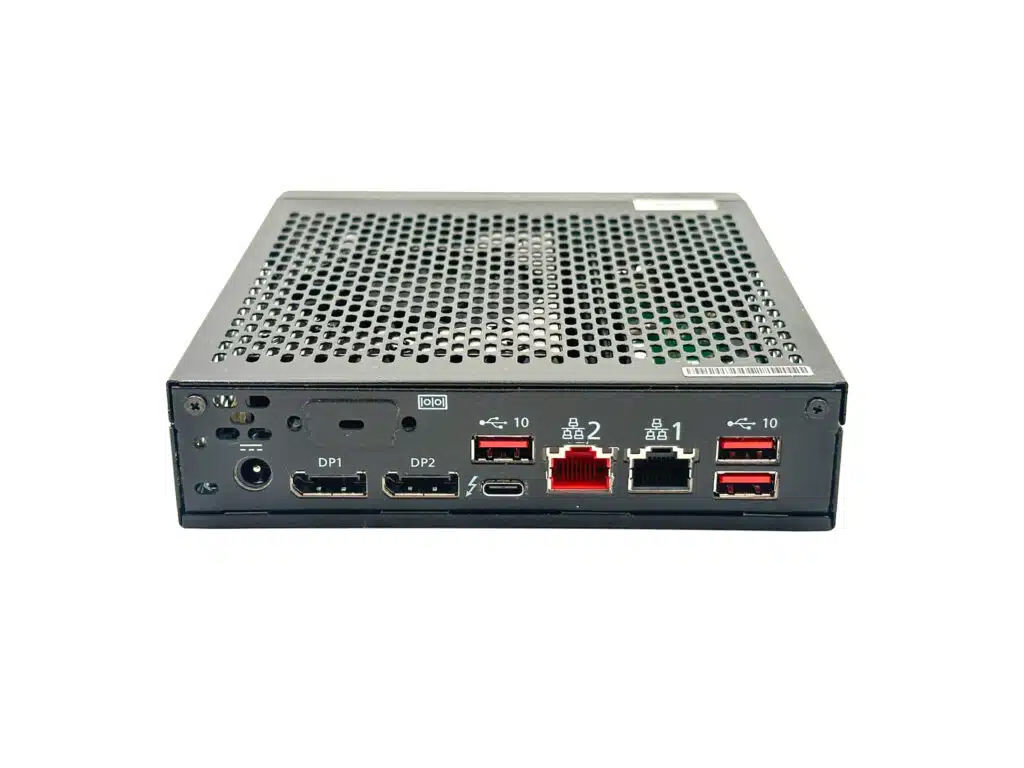

This is where mini PCs like our CORE 5 Ultra come into play: thanks to the Intel® Core™ Ultra 5 125U processor (with 2 Performance Cores & 10 Efficiency Cores) and integrated NPU with 11 TOPS, it can run AI models directly on the spot. This allows sensor data to be analyzed in real time and potential faults to be detected before they occur.

The advantages of predictive maintenance are obvious:

Predictive maintenance can bring enormous efficiency gains, particularly in sectors such as production, mechanical engineering, energy and transportation. This makes it a central component of modern Industry 4.0 strategies.

Many companies would like to introduce predictive maintenance, but don't know exactly where to start.

Fraunhofer IESE identifies three key success factors: good data, suitable models and well thought-out integration into existing processes.

For predictive maintenance to make economic sense, companies should start small. For example, with a pilot project on a critical machine, clearly defined goals and a scalable infrastructure. The system can then be transferred to other systems step by step.

A key success factor is the right hardware platform. This is because predictive maintenance applications require stable systems that run continuously, even in harsh industrial environments.

Our spo-comm industrial PCs are just right for this! They offer high computing power in the smallest of spaces, are temperature-resistant and durable in continuous operation. With integrated AI functions, for example via NUPs or optional accelerator cards, they can process sensor data directly without having to go via the cloud.

This saves bandwidth, reduces latency and makes the solution secure and independent - ideal for edge AI scenarios in industry.

As great as the advantages are, they do not come without challenges:

However, companies that take a strategic approach to this issue and adapt their processes accordingly will quickly benefit from more stable workflows and lower maintenance costs.

Predictive maintenance is more than just a buzzword, it is a real game changer for the industry. The use of modern sensor technology, AI and edge computing is turning reactive maintenance into an intelligent, data-driven process. Systems are not only monitored, but increasingly understand themselves when they need support.

With robust and powerful mini PCs such as the CORE 5 Ultra from spo-comm, such systems can be implemented reliably - right where the data is generated.

Although the vacation season was at its peak for us in September, we can shine with two new products...

Digital signage has long been much more than just static screens. In times of Industry 4.0, smart bu...

SCADA systems enable real-time monitoring and control of industrial processes and are central to Ind...

You need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More Information