22.07.2025

We take a look at the embedded AI solutions in our portfolio and show how our Edge AI industrial PCs can be used in practice - from simple entry-level solutions to scalable high-performance systems for complex scenarios.

What was just a dream of the future a few years ago is now a reality: artificial intelligence helps to maintain machines proactively, check quality automatically or control the flow of goods intelligently. And best of all, thanks to modern embedded AI solutions, data processing no longer has to take place in the cloud. Edge AI makes it possible for industrial PCs to make intelligent decisions directly on site - quickly, efficiently and safely.

It's not for nothing that our popular CORE PC will soon be called "Ultra". Equipped with the latest Intel® Core™ Ultra processor and integrated NPU (Neural Processing Unit), it is ideal for getting started with Edge AI and enables energy-efficient AI inference directly on the device. This makes it perfect for decentralized processing of sensor data, simple visual inspections or local control units - without the need for a permanent cloud connection.

A typical application scenario for the CORE 5 Ultra can be found in food processing, where the compact AI edge computer with integrated camera optics and AI software can detect color changes or irregularities in products in order to automatically sort out rejects. The real-time decision is made locally on the device - a classic application for embedded AI solutions in the edge computing industry.

When it comes to demanding AI workloads, the NOVA R680E comes into play. The powerful Edge AI industrial PC combines a powerful CPU with a wide range of expansion options, such as NVIDIA or Intel accelerator cards via PCIe. This makes it the ideal platform for deep learning conferences, compute-intensive image processing or predictive maintenance AI - all directly at the edge, without having to rely on the computing power of data centers.

In a modern intralogistics center, the NOVA R680E takes over the real-time analysis of data from conveyor belts, robot gripper arms and optical sensors. The system not only detects faulty packages or incorrectly placed products, but also uses AI algorithms to analyze the wear behavior of individual components. This allows failures to be detected at an early stage - a prime example of predictive maintenance AI at the edge.

For particularly computationally intensive AI applications, spo-comm is currently developing a new high-end edge system with a computing power of up to 1000 TOPS(Tera-Operations per Second). This system is specially designed for industrial use - for example in areas such as intelligent robotics, multi-camera inference in real time, automated production lines or edge training of smaller machine learning models.

The system is based on a powerful AI Edge Computer, which is built on a modern platform and uses a superchip that combines a 20-core CPU with a GPU. With 128 GB LPDDR5x memory and state-of-the-art networking technology, the system offers impressive performance for demanding AI applications. Designed specifically for developers, AI researchers and data scientists, the supercomputer offers unparalleled performance, scalability and advanced features in a compact, desktop-optimized format. It is ideal for developing edge AI applications with modern AI frameworks. Advanced networking technology allows two systems to be stacked to work together with AI models with up to 405 billion parameters.

In a networked production hall, the system is used in an autonomous inspection robot. It navigates independently through the plant, continuously records the condition of machines via several 4K cameras, checks safety zones and detects potential hazards or faults in real time. Local Edge AI processing enables the robot to react without delay, make decisions and simultaneously save relevant data for further analysis - a key component of modern edge computing industry concepts.

Whether as a compact entry-level solution or as a scalable high-performance system - our industrial PCs are designed to enable the implementation of a wide range of AI applications directly at the point of action. In this way, we create a basis for smart manufacturing processes, greater efficiency and more.

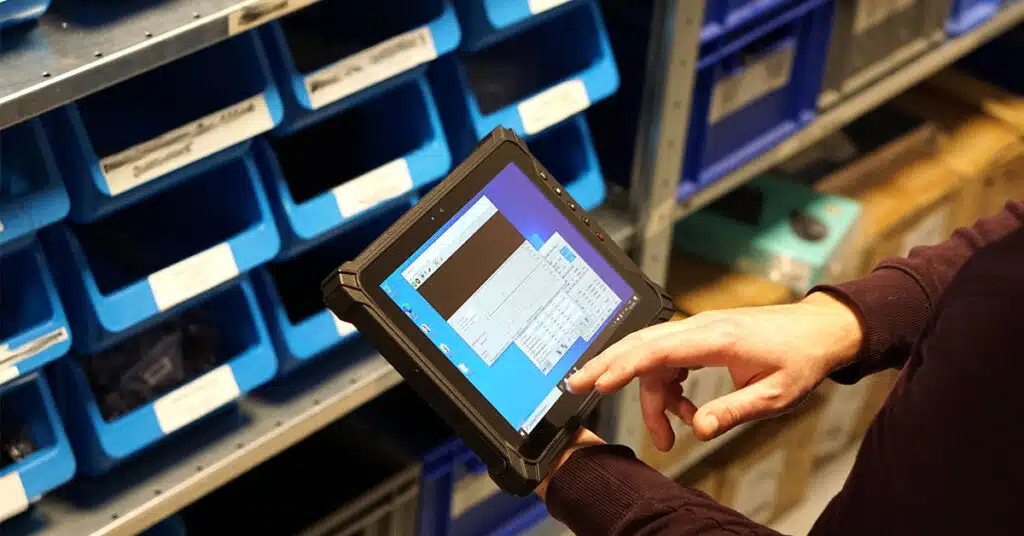

Whether in the industrial hall, in the warehouse or out in the field, mobile IT has to do much more ...

In many companies, it is not easy to find the right hardware for harsh environments. Before an indus...

Our industrial tablets are super flexible and robust. Robust explains itself thanks to the protectio...

You need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More Information